The SONEX® Acoustic Panel Adhesive has been specially formulated for use with our Sonex acoustic foam panels.

One 10.5-ounce tube installs approximately 16-24 square feet of Sonex® acoustic foam wall panels and fits into a standard caulking gun.

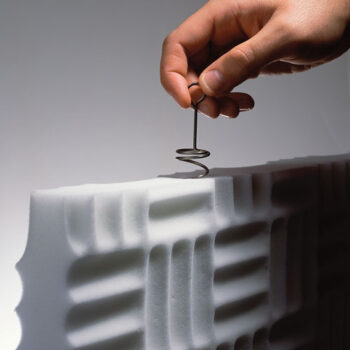

This adhesive makes installation hassle-free and provides a strong, permanent bond when adhering Sonex® melamine materials to walls or ceilings. Compatible with Sonex® Panels in both polyurethane and melamine foams. Sonex® Acoustic Panel Adhesive provides easy clean-up with water.